Dovetail Jig Tips

Cutting dovetails on a router-based jig is certainly easier than cutting them by hand. Still, there's a little bit of a learning curve. Here are some tips to help you get the most out of your jig.

(Mike Krivit)

Lubricate Surfaces

The easier it is for you to move

your

router across the jig, the better. If the router base gets hung up at

all the

router can rock, ruining the joint. A little lubricant goes a long way

toward

keeping everything going smoothly.

I routinely spritz the jig

template and

router base with a lubricant. Try it and you'll find that, by reducing

the

friction between the router and jig, it's suddenly easier to use the

jig.

Be

sure you're using a lubricant that's designed for these applications,

such as

Empire Manufacturing's Table Top Lubricant. Once it's dry, there's

nothing left

behind to migrate on to your wood and mess up your staining and

finishing.

Know The Score

You'll reduce the likelihood of

chipping

if, before cutting the full tails, you lightly score the face of the

vertical

tail board.

After your setup is complete, run the router left to

right

across the jig. Allow only the corner of the dovetail bit to contact the

face of

the material. This creates a slight shoulder. When the scoring cut is

complete,

cut the full dovetail.

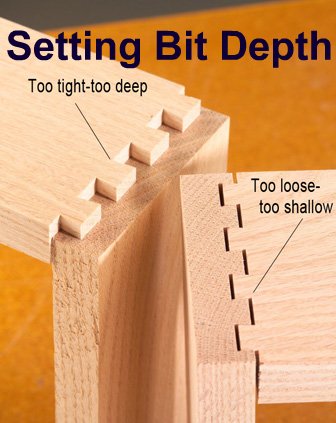

Setting Bit Depth

The fussiest part of getting good

dovetails from a router-based jig is setting the dovetail bit to the

perfect

depth. When the bit is set too deep, the joint will be too tight. When

the bit

is set too shallow, the joint will be too loose. The mantra that's been

stuck in

my head for years is "Too tight-too deep. Too loose-too shallow." I even

wrote

it on the board the jig is mounted on.

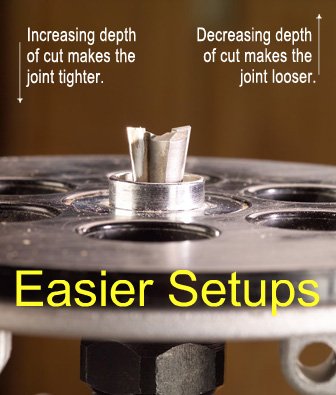

Easier Setups

Once you've cut a perfectly fitting

dovetail you can create a shortcut to make setup lots easier next time.

Cut an

extra dovetail joint and save the tail board. Mark it so you know it's a

setup

board for your jig.

The next time you need to cut dovetails insert

the setup

board the same way you'd normally insert a tail board. Set the depth of

cut of

the router bit by allowing it to "kiss" the shoulder on the tail board.

This

makes setting the bit depth significantly easier, and if you're careful

you'll

be dialed in close on the first try, but you should still do a test cut

in scrap

before working on parts from your project.